How Watt Window® helps glass manufacturers

See true production cost across every customer, job, and run.

Whether you manufacture products on behalf of customers or package and assemble them, your profitability depends on understanding cost by job, batch, or client.

Watt Window gives clear, load-level energy visibility so you can assign real energy cost to each run, even as schedules, customers, and operating conditions change.

Actionable insights for multi-client production

Batch-level cost clarity

See how energy use varies by product, customer, or run so pricing and margin decisions reflect real production cost.

Profitability under variability

Understand how timing, throughput, and equipment load affect cost across short runs and frequent changeovers.

Customer-ready reporting

Provide clear energy or emissions data when customers require it, without exposing proprietary processes.

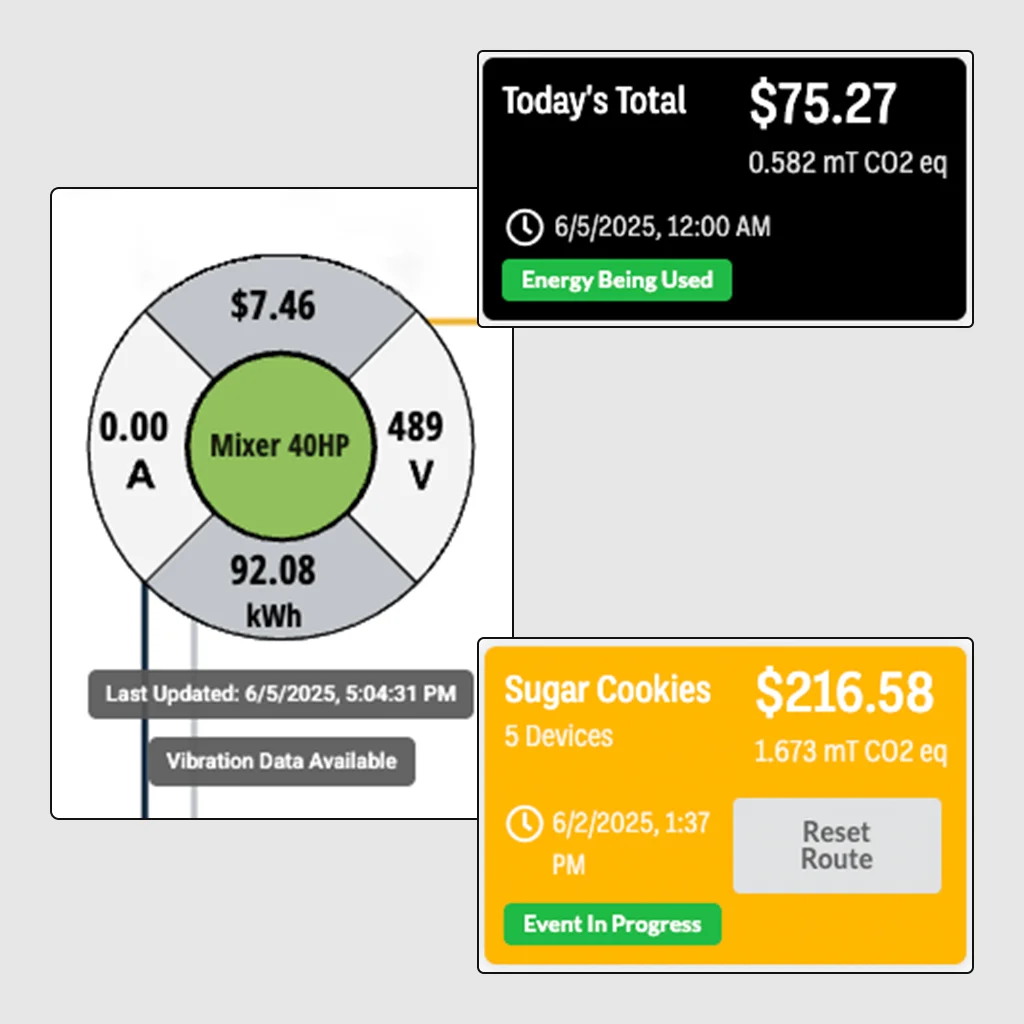

Assign energy cost to individual jobs and customers.

Watt Window captures frequent energy data by circuit, route, or load group.

That allows contract manufacturers and co-packers to attribute electricity cost to specific batches, SKUs, or customer runs, instead of spreading energy evenly across production.

Maintain margin clarity as conditions change.

Short runs, frequent changeovers, and varying equipment utilization can make energy cost hard to track.

Live visibility helps teams see how energy intensity shifts by time of day, equipment state, or run length, supporting better pricing and scheduling decisions.

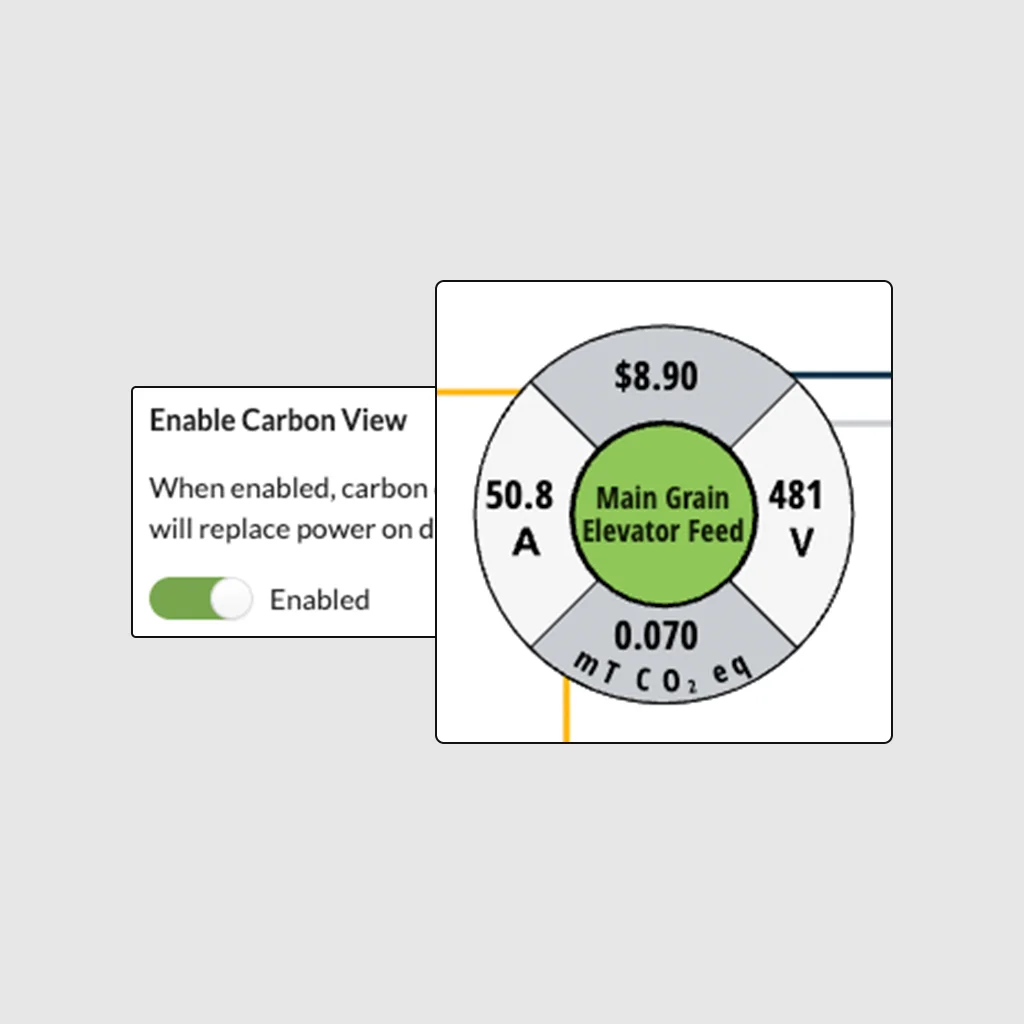

Support customer-driven reporting needs.

Some customers, particularly those operating in regulated markets, request energy or emissions data tied to production.

Watt Window provides reliable electricity-use data and derived carbon-equivalent metrics when needed, without capturing recipes, formulations, or sensitive production logic.

Integrate without disrupting operations or workflows

The system installs as a read-only layer on existing electrical infrastructure.

It does not interfere with automation, sequencing, or quality systems, making it practical in facilities with tight production schedules and limited downtime.

The bottom line for you

Contract manufacturers and co-packers operate with high variability and thin margins.

Watt Window turns electricity consumption into clear, job-level insight, helping teams price accurately, protect margins, and respond to customer reporting requirements without adding operational complexity.

Energy cost resolution for industry

Watt Window provides configurable, UL-listed smart-metering and monitoring hardware designed for industrial electrical systems.

Once installed, it records frequent energy, electrical, thermal, and optional vibration data across machines, lines, or load groups. The system converts that data into dashboards showing energy consumption, load behavior, cost attribution, and carbon-equivalent emissions for electricity use.

See How Watt Window fits contract manufacturing and co-packing.

Talk with our team and get a live solution overview