How Watt Window® helps recycling operations

See energy costs clearly. Protect margins as markets shift.

As margins tighten or swing with commodity prices, energy cost becomes one of the few levers that remains directly controllable.

Watt Window gives recycling operators clear, load-level visibility into where they use how much electricity, when it spikes, and how it affects cost across shifts, lines, or routes.

Actionable Insights for recycling operations

True energy cost drivers

See which shredders, furnaces, conveyors, and separation lines drive electricity spend at different times of day.

Margin protection under volatility

Understand how energy intensity shifts with throughput, material mix, or operating conditions so teams can respond faster.

Reporting-ready energy data

Provide defensible energy and emissions data when customers or regulators require it, without exposing proprietary operations.

Assign energy costs to real operations.

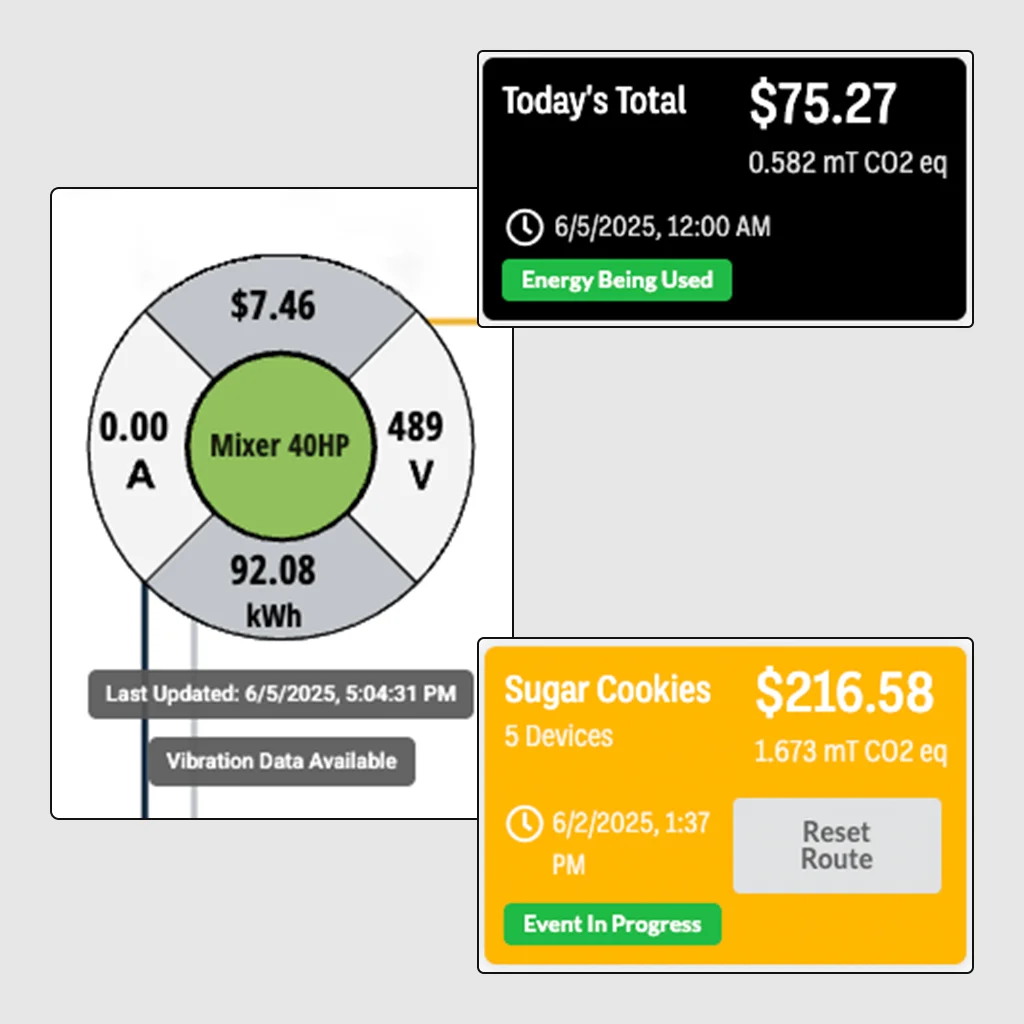

Watt Window captures frequent, load-level energy data across heavy electrical equipment.

That lets operators link electricity cost to specific lines, shifts, or processing stages instead of relying on plant-level averages.

Respond confidently to energy price and load swings.

Recycling facilities often see rapid changes in load as material mix, throughput, or operating schedules shift.

Live visibility helps teams spot spikes early and adjust operations before costs escalate.

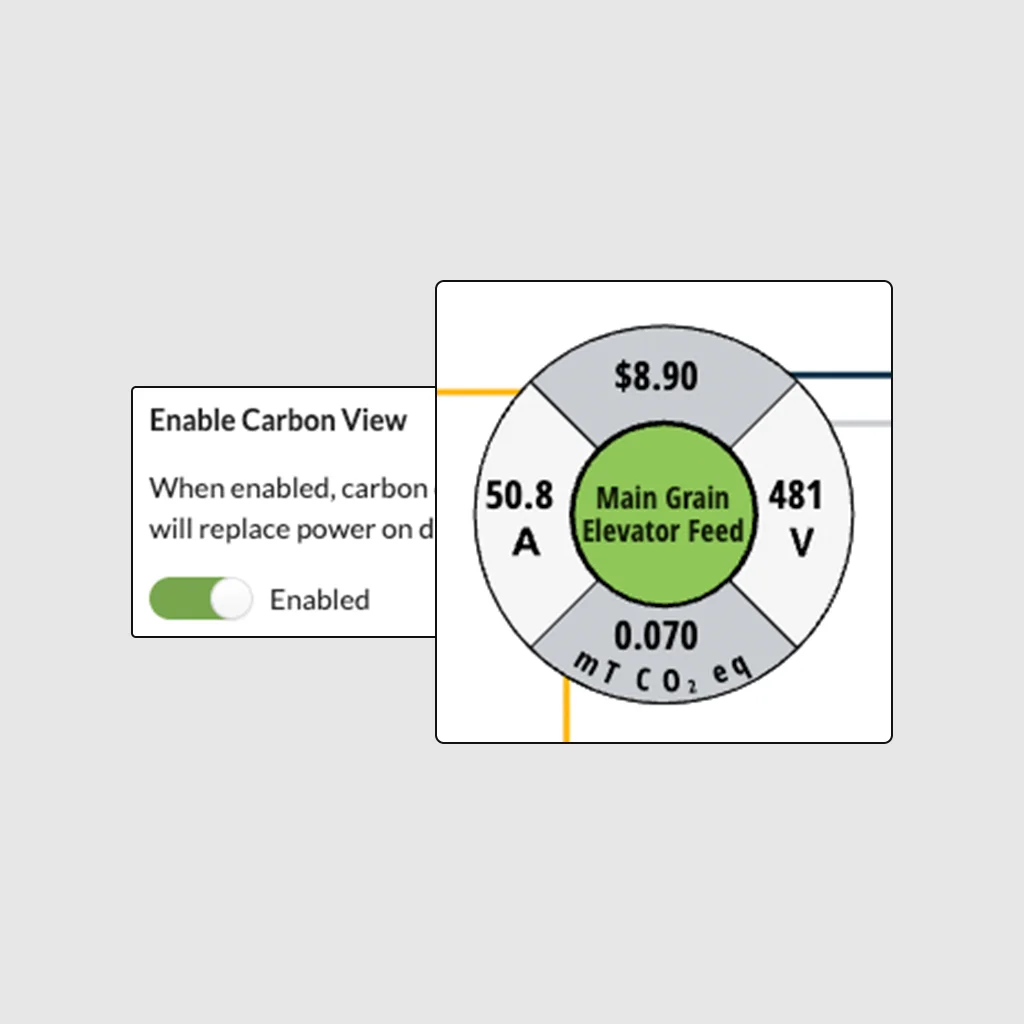

Support carbon compliance or customer reporting when required.

For customers operating in (or selling to) regions with energy or carbon reporting requirements, Watt Window provides reliable electricity-use data and derived carbon-equivalent metrics.

This supports reporting needs without capturing process recipes or sensitive operational detail.

Add operational awareness without disrupting production.

Watt Window installs as a read-only layer on existing electrical infrastructure.

It does not interfere with control logic or automation, making deployment feasible in active facilities or during scheduled downtime.

The bottom line for you

Metal recyclers operate in cost-sensitive environments shaped by volatile markets and high electrical loads.

Watt Window turns electricity consumption into actionable insight, helping teams protect margins, improve cost control, and meet reporting requirements when needed.

Energy cost resolution for industry

Watt Window provides configurable, UL-listed smart-metering and monitoring hardware designed for industrial electrical systems.

Once installed, it records frequent energy, electrical, thermal, and optional vibration data across machines and load groups. The system converts that data into dashboards showing energy consumption, load behavior, cost attribution, and carbon-equivalent emissions for electricity use.

See How Watt Window fits recycling operations.

Talk with our team and get a live solution overview