How Watt Window® helps ethanol plants

Real-time energy clarity to sharpen margins and uptime

As you run high-energy processes in milling, fermentation, distillation, and drying, Watt Window gives plant teams machine- and line-level visibility into energy use, equipment health, and operational risk.

Actionable Insights for ethanol production floors

Energy clarity

See real electrical use across mills, pumps, dryers, and routes. Replace assumptions with measured cost drivers.

Operational confidence

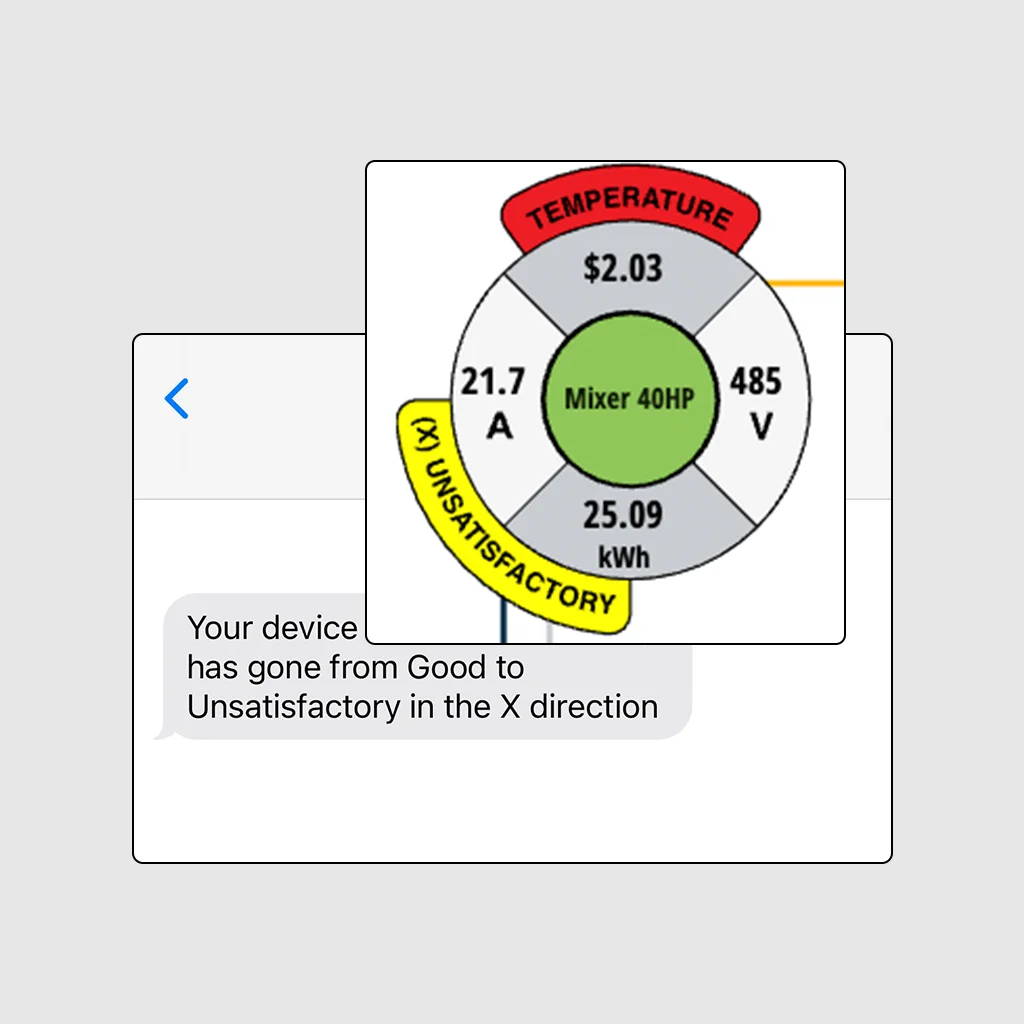

Clear signals help teams respond before energy drift or equipment stress impacts yield or uptime.

Cost and carbon awareness

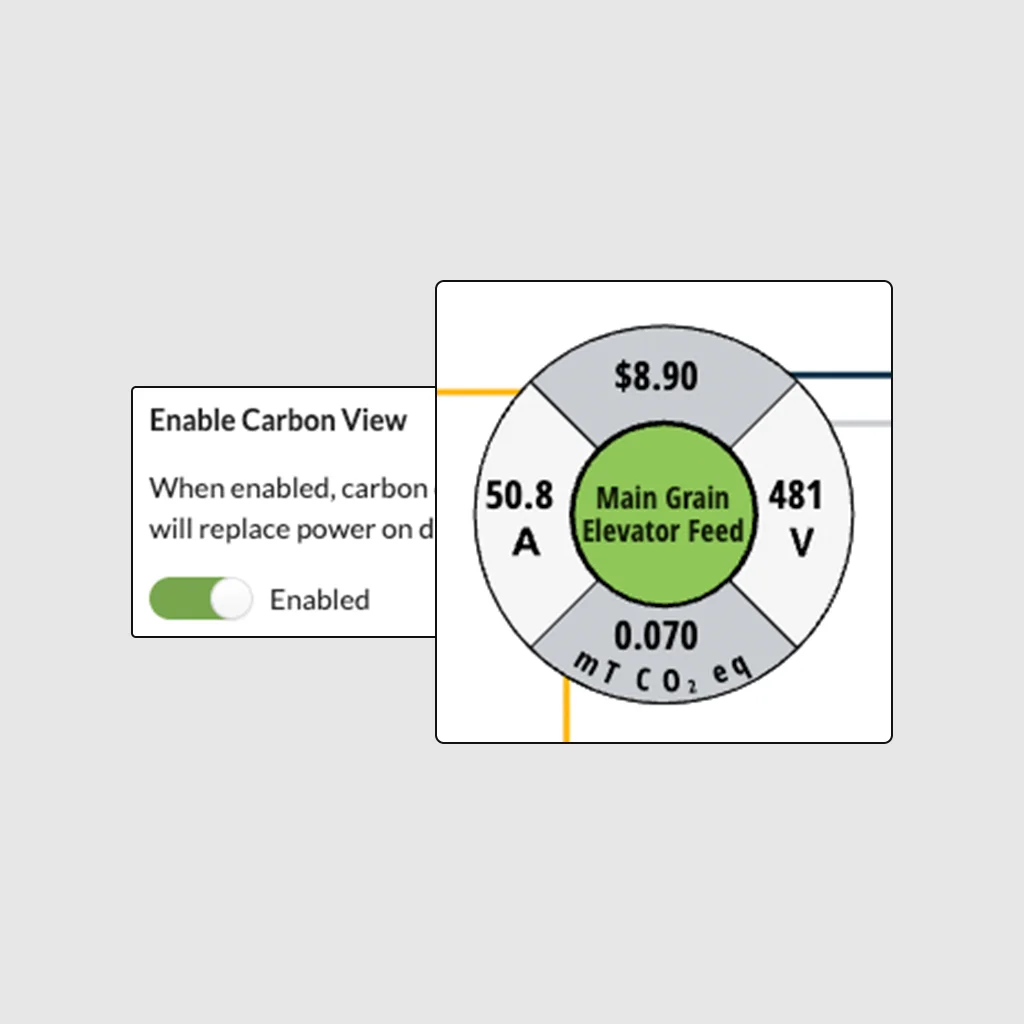

Track financial and emissions impact of production in practical, plant-level terms.

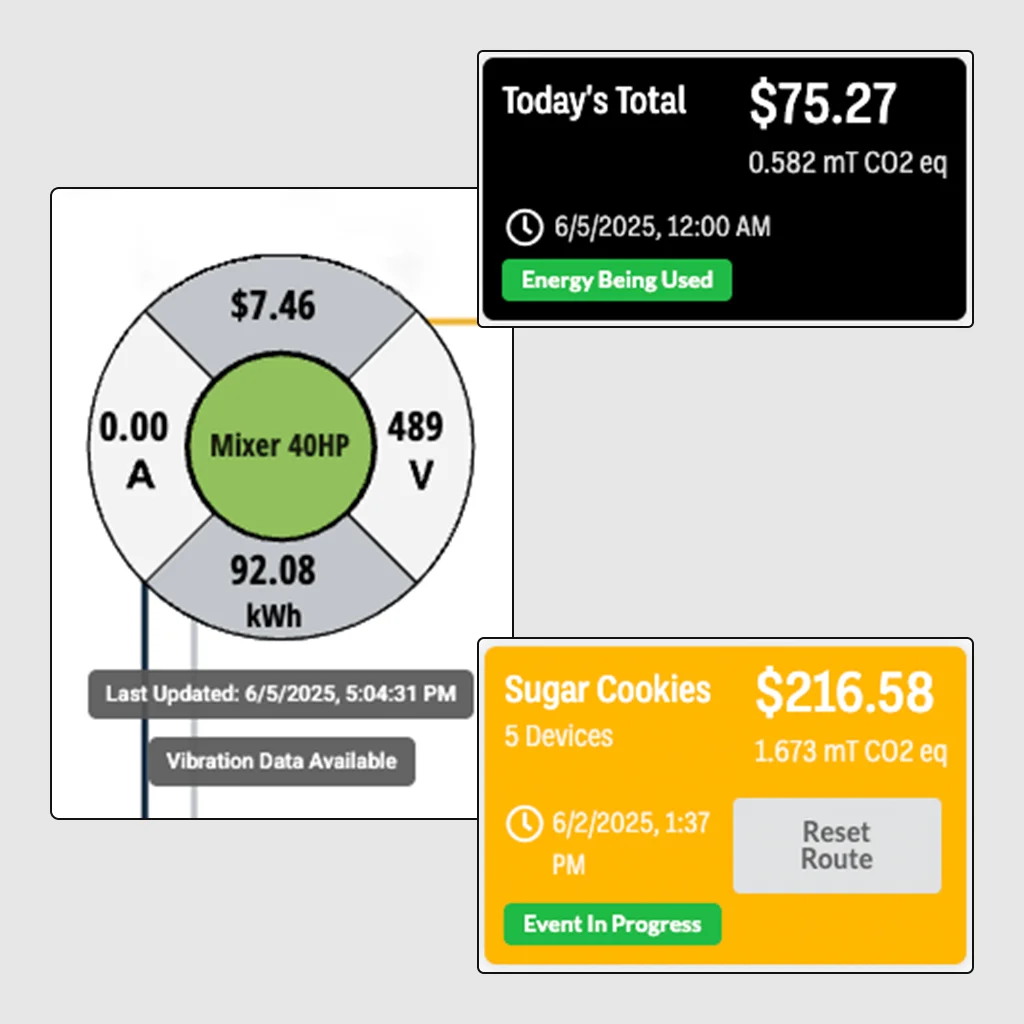

Assign true energy cost by batch, shift, or line.

Watt Window captures energy data every 30 seconds, covering individual motors and dryers as well as full-plant consumption. That lets operators track energy use by batch, line, or production phase.

That clarity supports precise cost control, margin tracking, and informed decisions on production scheduling or maintenance.

Spot inefficiency or machine fatigue before it hurts throughput.

High-load systems such as grinders, pumps, distillation fans or dryers often hide early signs of wear or inefficiency.

Continuous monitoring and alerting help detect abnormal load patterns or motor stress early, letting teams intervene before failure, protecting throughput and steam-balance integrity.

Support energy and carbon management goals without exposing process details.

Watt Window tracks only electrical, vibration, and thermal signatures. Dashboards show energy, cost, and carbon-equivalent emissions.

That delivers operational transparency and supports carbon or sustainability reporting while keeping process recipes and control logic private.

Integrate cleanly into existing infrastructure with minimal interruption.

Our system is modular and designed to work with existing MCCs, VFDs, or legacy electrical gear.

Licensed industrial electricians can install it without rewiring automation or control systems.

That makes rollout realistic in existing plants or during upgrades.

The bottom line for you

Ethanol plants face high energy use, variable loads, and tight margins. Watt Window gives you the necessary visibility to optimize your production energy.

With that data you can manage energy cost, monitor equipment health, plan maintenance, and make data-driven operational decisions near-live, for better cost efficiency and reliability.

Energy cost resolution for industry

Watt Window provides configurable, UL-listed smart-metering and condition-monitoring hardware for industrial electrical systems.

Once installed, it captures energy, electrical, thermal, and vibration data across machines and lines. The system delivers dashboards with load profiles, energy consumption, cost, carbon-equivalent emissions, and equipment-stress indicators, giving operators clarity without exposing process control or logic.

See How Watt Window fits ethanol producers

Talk with our team and get a live solution overview